1

The paper is delivered straight from our mill in Étival, a town in the nearby Vosges region. Here, a 16,000 meters reel is being fed through several cylinders to obtain just the right tension for printing

The stationery firm “Papeteries Vérilhac Frères” was founded in Lyon, France, in 1932 by two brothers, Henri and Robert Vérilhac. They came from a family of paper merchants and their market extended from France across all of North Africa.

At first they sold notebooks and stationery products, and then, in 1934, they started manufacturing and selling the Rhodia pads. In 1997, Rhodia was bought by Clairefontaine.

The production units were then grouped together near Mulhouse (Haut-Rhin, France) and the company Clairefontaine Rhodia was born.

All the Rhodia notepads are manufactured in the Alsace region of eastern France, at our plant in Mulhouse, which dates back to 1840!

1

The paper is delivered straight from our mill in Étival, a town in the nearby Vosges region. Here, a 16,000 meters reel is being fed through several cylinders to obtain just the right tension for printing

2

Grids, lines or dots are printed....

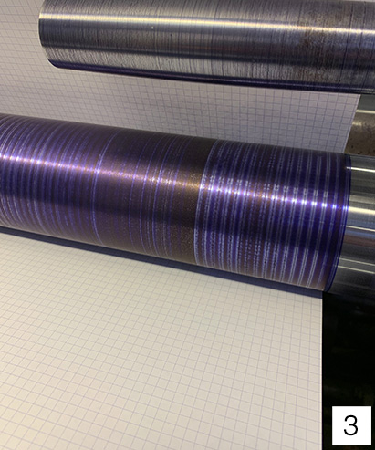

3

onto the paper with inked cylinders.

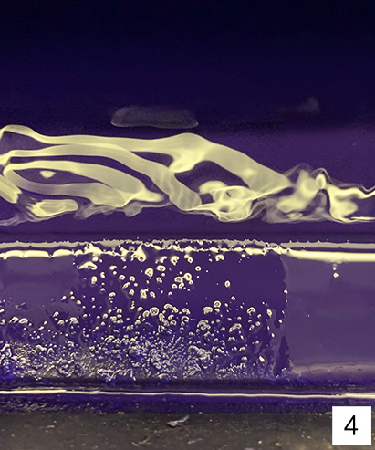

4

The ruling is printed with water-based ink.

5

The microperforations, for easy sheet removal, are made once the rulings have been printed

6

Then, the 80 sheets that make up each notepad block, are counted and assembled.

7

The cardboard backing is positioned.

This stiff back cover ensures that the pad holds its shape, providing support if you don’t have anything to lean on.

8

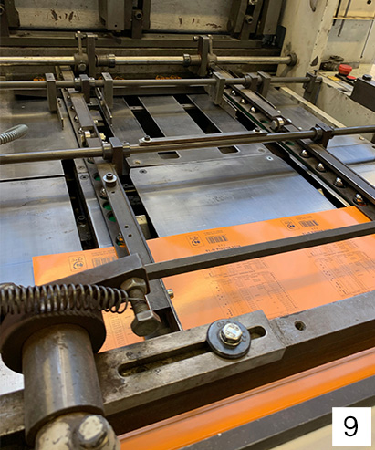

The first cutting phase takes place. Then, the adhesive is applied to bind the paper and cardboard together.

9

The front cover grooves are made and the cover is then positioned on top of the notepad block.

10

The staples are inserted using a unique process, known as “Sangrif”. This leaves no staples exposed on the back of the pad, so you won’t hurt yourself, get them caught on your clothes, or scratch your desk.

11

The cover is glued to the top end of the notepad block and then folded over.

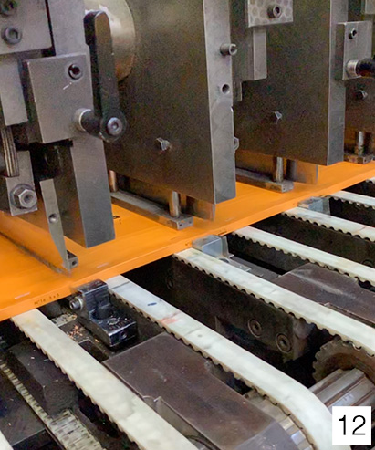

12

The final cutting is the last stage of the manufacturing process.

Actually, the notepads are then packaged, crated and labelled for dispatch to shops all over the world.

13

Humans are involved at every stage of the manufacturing process. They program the machines, control them, make the adjustments for each manufacturing stage, and supervise all the operations.

check_circle

check_circle